Practical AI Guidance for Yield Forecasting and Production Planning in Crop Production and Management

You’re operating in an industry where margins, timing, and informed decisions determine success. AI is not a gimmick; it’s a practical tool that can help you forecast yields more accurately and plan production with greater efficiency. This article gives you tactical advice, realistic expectations, and an implementation roadmap so you can adopt AI in yield forecasting and production planning without getting lost in hype.

Why yield forecasting and production planning matter for your business

Yield forecasting and production planning are the backbone of crop production economics and supply reliability. When you can predict yield with confidence, you reduce financial risk, optimize input use, schedule labor and machinery effectively, negotiate better contracts, and improve relationships with buyers. For you as a business leader, better forecasts translate to improved cash flow, reduced waste, and the ability to invest more strategically.

How AI is changing the way you work

AI turns huge, messy data streams—satellite images, sensor logs, weather models, and market data—into actionable insights. Instead of relying solely on historical averages or intuition, you can use predictive models that adjust to current season dynamics. You’ll be able to detect stress earlier, re-prioritize resources, and run scenario simulations to see the financial impact of different operational choices. Essentially, AI moves you from reactive to proactive management.

Business benefits you should expect

When you invest in AI for yield forecasting and production planning, expect improvements in forecast accuracy, reduced input costs through targeted interventions, higher harvest efficiency, and more reliable delivery to buyers. You’ll also see non-monetary benefits like better risk management, improved traceability, and the ability to demonstrate sustainability metrics. These improvements compound over multiple seasons when you continuously refine models and processes.

Core data sources and inputs you need

You can’t build robust AI without data. Core inputs for yield forecasting include historical yield records, soil maps, planting dates, seed and input application records, irrigation logs, pest and disease observations, farm machinery logs, local and gridded weather data, and remote-sensing imagery (satellite and drone). Each of these gives you a different lens on the crop’s growth and stress factors, and combining them creates a richer predictive picture.

Remote sensing and imagery

Remote sensing has become indispensable for field-scale insight. Satellite imagery provides regular, broad coverage and is great for monitoring phenology and biomass over entire regions. Drone imagery gives you high spatial resolution for targeted problem diagnosis. You’ll use vegetation indices, canopy cover, and change detection over time to feed models that estimate biomass and stress. To leverage this effectively, ensure consistent time-series imagery and standardize imaging protocols.

Weather and climate inputs

Weather is a primary driver of yield variability. You’ll need historical weather, forecast models, and seasonal climate outlooks. Integrate daily temperature, precipitation, solar radiation, humidity, and evapotranspiration estimates into your models. For production planning, you’ll also use short-term forecasts (7–14 days) to schedule labor and irrigation and seasonal outlooks to manage contracts and risk. Be explicit about the temporal resolution you require for each decision layer.

Soil, management, and field metadata

Soil texture, organic matter, drainage class, and pH influence water availability and nutrient dynamics, so you need accurate soil maps or sensor data. Management data—planting date, cultivar, seeding density, fertilizer and pesticide applications, irrigation events—are critical in explaining yield variance. If you don’t already capture this metadata systematically, prioritize building a minimal standard digital record for every field.

Yield and harvest records

Historical yields are the target you want to forecast, so ensure harvest records are precise and geolocated if possible. Combine combine-harvester log data with manual records to reconcile discrepancies. Time-series yield maps are highly valuable because they let you train spatial models that account for persistent field heterogeneity rather than treating every field as uniform.

Data quality, governance, and practical collection tips

You’ll quickly find that data quality determines model quality. Establish a data governance baseline: consistent formats, clear ownership, versioning, and metadata. Standardize units and timestamps across sources. Validate sensor calibrations regularly and train field staff on correct data entry processes. Where historical digital records are sparse, plan a short campaign to backfill critical fields and validate remote-sensing proxies with ground truth.

Handling missing, noisy, or biased data

Expect gaps and noise. Use interpolation for short missing weather or sensor gaps, but be cautious with long gaps—you may need to exclude unreliable segments. Where human observation data is biased or inconsistent, create simple validation checks or cross-reference with objective sensors or imagery. For biased historical records, consider recalibrating with a recent reliable subset before training models.

Modeling approaches you can choose

You can pick from statistical models, classical crop models, machine learning (ML), deep learning (DL), or hybrid approaches that combine process-based knowledge with data-driven methods. Each approach has trade-offs: statistical models are interpretable but may lack complexity; crop models simulate physiological processes but need lots of fine-grained inputs; pure ML can find patterns in large datasets but requires many examples and can overfit. Choose the approach that balances interpretability, data availability, and the decisions you need to support.

Process-based crop models vs. data-driven models

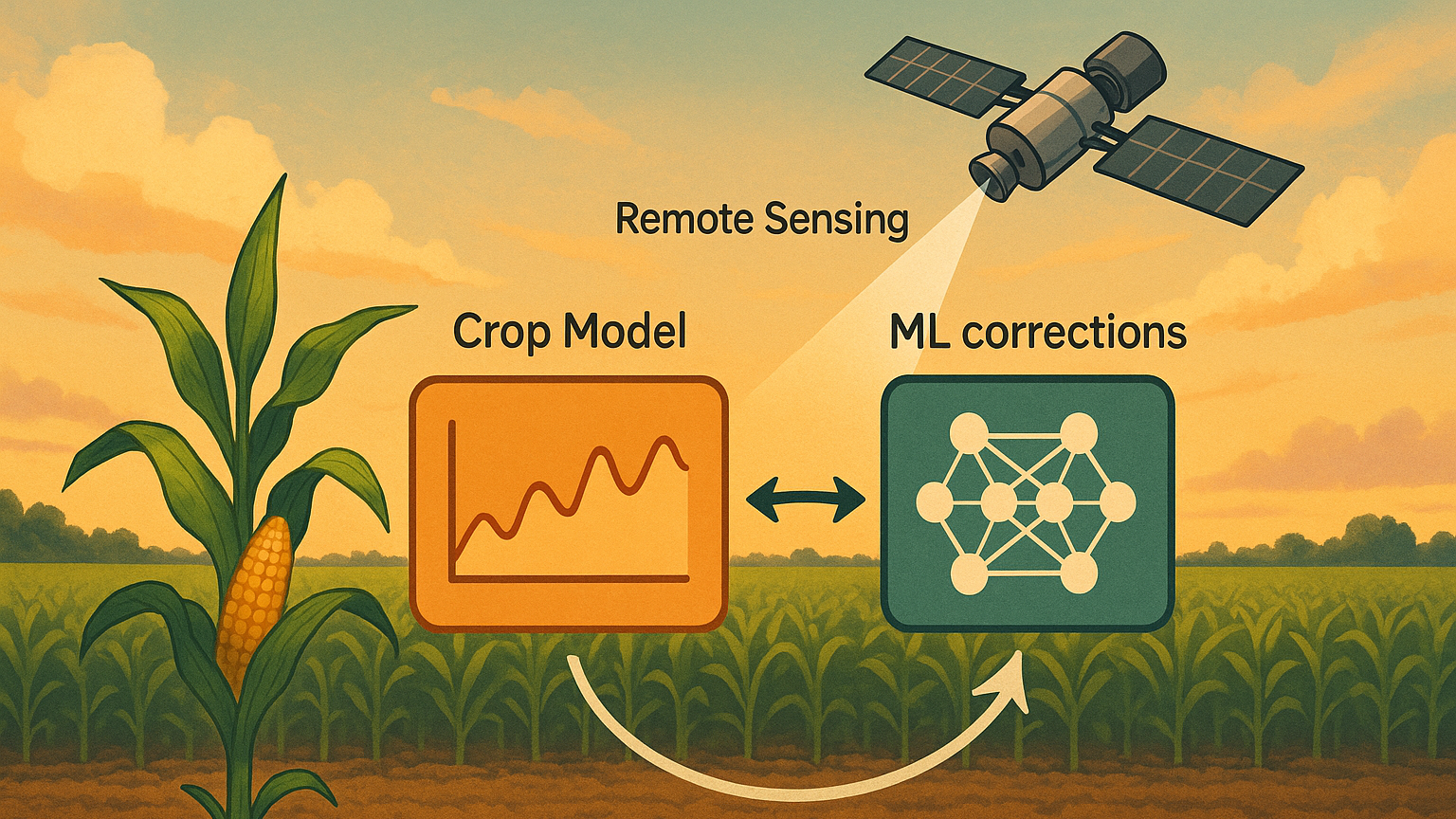

Process-based models (e.g., DSSAT, APSIM) simulate crop growth mechanistically, so they’re great when you need to understand causes and run “what-if” scenarios around management. Data-driven models (random forests, gradient boosting, neural networks) excel when you have lots of correlated data and want high predictive accuracy. In practice, you get the best of both worlds by using crop models to generate features or priors and ML models to capture residual patterns.

Ensemble and hybrid models

Ensembles—combining multiple model outputs—reduce risk from any single model’s biases and often improve robustness. Hybrids that merge crop-model outputs with remote sensing and ML corrections are particularly effective: you leverage domain knowledge while letting data fill gaps. These hybrid strategies usually quote better real-world performance and provide more actionable uncertainty estimates for planning.

Feature engineering and agronomic variables you should include

Design features that capture season progression, stress events, cumulative water balance, heat units, and phenological stages. Use vegetation indices (NDVI, EVI), thermal stress indices, and anomalies relative to long-term normals. Include management attributes such as fertilizer timing and quantity, irrigation schedule, and cultivar traits. Derive rolling-window statistics (e.g., cumulative rainfall over 30 days) rather than only instantaneous values; these more closely reflect crop responses.

Temporal and spatial resolution considerations

Match data resolution to the decision you’re supporting. Field-level operational decisions need high spatial resolution (sub-field, sometimes meter-level) and daily updates. Regional supply planning can work with coarser spatial resolution and weekly temporal updates. Avoid the trap of chasing ultra-high resolution everywhere—apply the necessary granularity where it changes decisions.

Measuring uncertainty and explainability

You must deliver not only a forecast but also a confidence range and an explanation of drivers. Use probabilistic models, quantile regression, or ensemble spreads to quantify uncertainty. Provide feature importance or SHAP values to explain why a forecast looks the way it does. In production planning, use scenario runs to demonstrate how different weather outcomes affect yield and cash flow so your operations and finance teams can plan for contingencies.

Communicating forecasts to non-technical stakeholders

Frame forecasts in terms your teams use: expected yield per hectare, expected harvest window, probability of a shortfall, and the operational actions the forecast suggests. Combine numbers with simple visuals and textual recommendations so agronomists, operations managers, and buyers can take action without needing to interpret raw model outputs.

Production planning and optimization with AI

AI helps you plan planting schedules, irrigation, labor, equipment allocation, harvest timing, and logistics by linking forecasted yield to resource constraints and market opportunities. Formulate production planning as an optimization problem: maximize profit or minimize cost subject to constraints like labor availability, storage capacity, contract obligations, and commodity price forecasts. Use mixed-integer programming or heuristic solvers for scheduling, and integrate forecast uncertainty through robust or stochastic optimization.

Operationalizing scheduling and resource allocation

Integrate AI outputs with your farm management system so schedules and work orders update automatically as forecasts change. For example, if predicted yield increases in a zone, the system should flag the need for additional harvest crews or storage. Automated alerts and prioritized task lists help you react quickly without manual re-planning.

Integrating AI into existing workflows and systems

You won’t replace your entire workflow overnight. Start by integrating AI outputs into existing dashboards, mobile apps, or farm management platforms you already use. Ensure APIs and data connectors exist between sensors, imagery repositories, ERP systems, and decision support tools. Prioritize writable integrations where decisions flowing from AI can be logged back into your management system for traceability.

Edge vs. cloud processing

Decide where processing happens. Use edge processing for low-latency tasks (e.g., on-drone analytics, local irrigation controllers) and cloud for heavy, cross-field model training and ensemble forecasting. Edge reduces bandwidth and latency but needs more robust device management; cloud offers scalability and easier model monitoring.

Choosing vendors, tools, and open-source options

You can buy end-to-end farm AI SaaS, combine best-of-breed vendors, or develop in-house with open-source stacks. Evaluate vendors on data portability, model transparency, integration APIs, and support for domain specialists. If you build in-house, leverage mature libraries (scikit-learn, XGBoost, TensorFlow/PyTorch) and geospatial tools (Google Earth Engine, rasterio, GDAL). Prioritize interoperability—pick tools that won’t lock your data into proprietary formats.

Questions to ask potential vendors

Ask vendors about their training data provenance, how they validate models, how they quantify uncertainty, and how their solution integrates with your existing systems. Ensure you retain rights to your data and can export models or results. Seek case studies or proofs of concept in your crop types and agro-climatic zone.

Model validation, KPIs, and monitoring

Define KPIs you’ll monitor: mean absolute error and bias in yield forecasts, prediction interval coverage, improved harvest scheduling accuracy, reduction in input use, and improved gross margin per hectare. Validate models using cross-season and cross-field testing, not just random splits, to ensure spatial and temporal generalization. Set up continuous monitoring for model drift, data quality issues, and changes in agronomy or market conditions that might invalidate assumptions.

Governance for model updates

Create a cadence for retraining and for reviewing model performance with agronomists. Use version control for models and data, and maintain a changelog for model updates and feature changes. Define thresholds that trigger retraining or human review—e.g., a rise in forecast error above a set limit or a change in input distribution.

Practical project roadmap: pilot to scale

Start small with a well-scoped pilot: choose one crop, a manageable number of fields, and a clear decision outcome (e.g., improve pre-harvest yield forecast accuracy by X%). Validate models over a full season or two and measure operational impacts. After successful pilots, scale horizontally (more fields/crops) and vertically (integrate with procurement and logistics). Keep iterations short and focus on delivering tangible operational improvements each season.

Roles and change management

You’ll need a cross-functional team: agronomists, operations managers, data engineers, data scientists, and a product owner who understands farm business priorities. Invest in training and change management so field staff trust outputs and know how to act on them. Build simple, two-way feedback loops so users can flag model issues and enrich training data.

Cost considerations and ROI estimates

Costs include sensors and imagery subscriptions, cloud compute, software licenses or development, personnel, and training. Offset these with savings from reduced inputs, more efficient labor, improved yield capture, and better contract pricing enabled by reliable forecasts. Build an ROI model that accounts for seasonality and learning; many operations see payback within 1–3 seasons when pilots are carefully targeted and linked to operational decisions.

How to measure ROI practically

Track metrics like reduced fungicide or fertilizer use per hectare, improved yield relative to control fields, faster harvest turnaround, and reduced post-harvest losses. Translate these into dollar savings and compare against project costs. Include qualitative benefits too, like improved buyer confidence and reduced risk premiums.

Risks, biases, and ethical considerations

AI can amplify biases if training data isn’t representative of your fields or seasons. Be aware of model overfitting to specific cultivars or management regimes. Data privacy and ownership are also important if you work with third-party providers—ensure clear contracts. Ethically, don’t automate decisions that should have human oversight, especially where livelihoods are at stake. Use AI to enhance human decision-making, not to replace human judgment entirely.

Legal and compliance issues

Depending on your region, you might face regulations on data transfers, especially if using cloud providers across borders. Be mindful of intellectual property clauses in vendor contracts and ensure you have rights to use and export your data. In contract farming setups, be transparent with suppliers about how their data is used.

Common pitfalls and how to avoid them

A frequent pitfall is chasing perfect accuracy instead of actionable improvements. Avoid overcomplicated models you can’t explain or maintain. Don’t ignore domain expertise—agronomists should be embedded in model design. Finally, don’t treat AI as a one-time project: plan for maintenance, updates, and continuous improvement.

Quick checklist to avoid common mistakes

- Start with clear business questions and measurable KPIs.

- Ensure basic data governance and high-quality ground truth.

- Pilot on a focused scope before scaling.

- Combine agronomy expertise with data science.

- Monitor models continuously and plan for retraining.

Case examples and illustrative scenarios

Imagine you operate a medium-sized vegetable farm. By combining remote-sensing-derived NDVI trends with irrigation logs and daily weather forecasts, you implement an ML model that flags zones likely to underperform three weeks before harvest. You reallocate water and labor to stressed zones, deploy targeted foliar feeds, and adjust harvest schedules. Over a season, you reduce underperforming hectares by 30% and cut post-harvest losses through better scheduling—demonstrating how AI-driven forecasting can create immediate operational value.

Regional planning and supply chain use case

On a regional level, a cooperative can aggregate forecasts from member farms to produce a supply forecast for buyers. This enables better contract negotiation and reduces penalties from missed deliveries. AI-driven probabilistic forecasts enable you to engage in flexible contracting strategies that protect margins while maintaining market relationships.

Scaling up: operations, training, and culture

Scaling AI requires institutionalizing data capture, creating feedback loops, and updating SOPs. Train field teams to trust and use AI outputs; provide simple interfaces and mobile notifications. Celebrate quick wins and collect user feedback to improve the product. Encourage a culture where data-driven suggestions are tested, validated, and incorporated into standard practice.

Long-term strategy for continuous improvement

Plan for multi-year improvement to model accuracy and process integration. Each season’s data improves your models and your understanding of the decision value chain. Allocate budget for ongoing model maintenance, new data sources, and incremental feature development to capture additional value over time.

Practical tools and technologies to explore

There are multiple tools across the stack: satellite platforms (Sentinel, Planet), geospatial processing (Google Earth Engine), ML libraries (scikit-learn, XGBoost, TensorFlow, PyTorch), farm management software with APIs, and optimization solvers for production planning. Cloud providers offer managed services that reduce devops overhead. Choose technologies that align with your team’s skills and your data governance needs.

When to build vs. buy

If your data or crops are highly specialized, or you require competitive differentiation, building in-house may be justified. If you want speed to value and standard crop coverage, vendors can get you started faster. Hybrid approaches—using vendor platforms while developing proprietary models or features—are common and often optimal.

Final recommendations and first steps you should take

Start with a narrow, measurable pilot and build trust through demonstrated operational value. Ensure you have a minimum data governance framework and capture critical ground truth. Combine domain expertise with data science and choose tools that integrate with your workflows. Measure ROI and risks, and iterate seasonally. Keep the human in the loop and use AI to augment decisions rather than automate them blindly.

You’ve taken the first step by reading this—now scope a pilot: pick one crop, define the business question, inventory your data, and schedule a seasonal timeline for model validation. With deliberate steps and cross-functional collaboration, you can turn AI forecasts into better decisions, lower costs, and stronger relationships with buyers.

If you found this article useful, please clap the article, leave a comment with your questions or experiences, and subscribe to my Medium newsletter for updates and practical case studies on AI in agriculture.