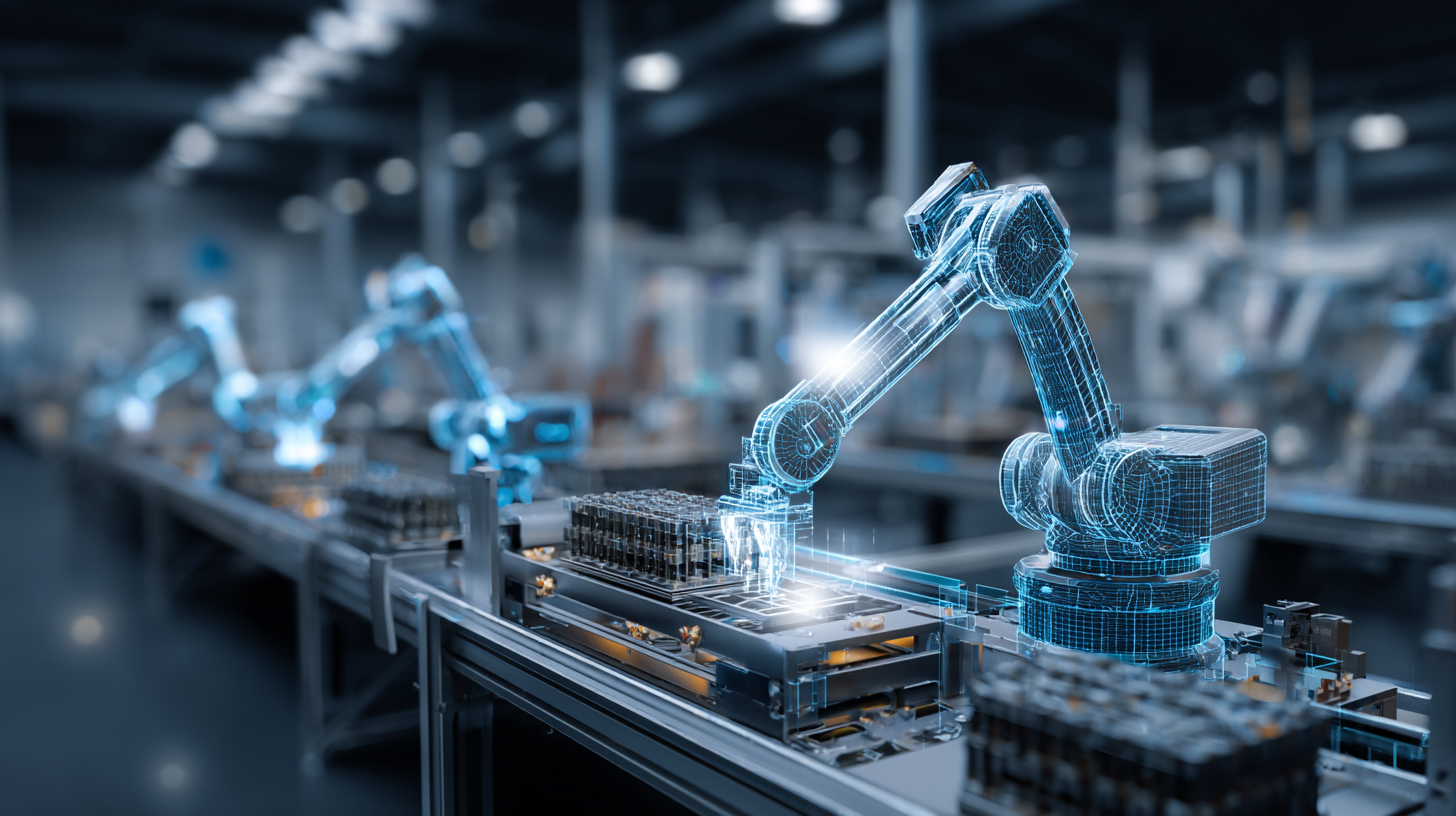

AI in Manufacturing: Transforming Production Processes

AI has taken the world by storm, and its influence has permeated numerous industries, including manufacturing. As you delve into the transformative potential of artificial intelligence within this field, you’ll find that it’s not just about robots and automation; it’s about evolving the entire production process. This article will explore various aspects of AI in manufacturing, from predictive maintenance to supply chain optimization, providing actionable insights and real-world examples.

Understanding AI’s Role in Manufacturing

Artificial intelligence refers to the simulation of human intelligence processes by machines, particularly computer systems. In manufacturing, AI plays a pivotal role in improving efficiency, reducing costs, and enhancing product quality. By integrating AI into your operations, you can streamline workflows and make data-driven decisions faster than ever. This is essential in a landscape where agility and responsiveness are crucial for success.

Imagine your production line operating smoothly, with machinery that predicts failures before they happen, schedules optimized for labor efficiency, and inventory that manages itself. This is the promise that AI offers, transforming traditional manufacturing practices into modern, data-driven processes that enhance output and effectiveness.

Predictive Maintenance: A Game Changer for Manufacturing

One of the most practical applications of AI in manufacturing is predictive maintenance. This approach utilizes machine learning algorithms to predict when equipment is likely to fail, allowing you to perform maintenance before catastrophic breakdowns occur. Not only does this save you from costly repairs and downtimes, but it also extends the lifespan of your equipment.

When you implement predictive maintenance, you’re not just reacting to problems; you’re proactively addressing potential challenges. For instance, if sensors indicate that a certain component of your machinery is degrading, you can intervene immediately. This method enhances reliability and efficiency, allowing your production process to stay uninterrupted. Furthermore, with lower maintenance costs and increased asset lifespan, the financial benefits are clear.

AI-Enhanced Supply Chain Management

The supply chain is the backbone of manufacturing, and integrating AI into this process can yield significant improvements. Through advanced analytics, AI can help you make better decisions regarding inventory management, demand forecasting, and supplier relationships. By anticipating demand fluctuations, you can adjust your production levels accordingly, preventing overproduction and waste.

Utilizing AI algorithms, you’ll be able to analyze vast amounts of data in real time, helping you devise strategies that are both agile and informed. Imagine seamlessly coordinating with suppliers and logistics to ensure that raw materials arrive exactly when you need them. This kind of precision not only minimizes stockpiling and reduces costs but also enhances your ability to respond promptly to market changes.

Quality Control Through AI Vision Systems

Quality control is critical in manufacturing, and AI vision systems are transforming how you ensure product quality. By employing computer vision and machine learning, you can automate inspections, identify defects, and maintain high standards.

Consider a production line where cameras are equipped with AI vision technology, inspecting every product as it moves along. Instead of relying solely on human oversight, AI can analyze images and spot discrepancies. This not only speeds up the inspection process but also enhances accuracy. Fewer defects mean happier customers and decreased costs associated with returns and rework, making AI-powered quality control a win-win for both manufacturers and consumers.

Enhancing Worker Safety with AI

Worker safety is paramount in any manufacturing environment, and AI is stepping in to help enhance safety protocols. Machine learning models analyze data from previous incidents to identify patterns and predict potential safety hazards. With this intelligence, you can proactively implement changes to improve working conditions.

For instance, AI systems can monitor worker movements and detect unsafe behavior or environments, sending alerts in real time. By providing safety gear equipped with sensors, workers can be monitored for signs of fatigue or distraction. This approach not only helps you comply with occupational health regulations but also fosters a culture of safety within your organization.

Challenges in Implementing AI in Manufacturing

Despite the numerous benefits, implementing AI in manufacturing is not without its challenges. One of the foremost concerns is the need for data. Accurate and comprehensive data is essential for training AI algorithms, and many organizations struggle to collect and manage this data effectively.

Additionally, workforce adaptation poses another obstacle. As you incorporate AI technologies, it’s vital to ensure your team is on board and adequately trained to work alongside these systems. If not addressed, resistance to change may hinder the adoption process. Developing a robust AI awareness training program can help alleviate these concerns, fostering a smoother transition and engagement with AI solutions.

AI Governance: Establishing Ethical Frameworks

As with any advanced technology, the introduction of AI raises ethical concerns, particularly in the realm of employment. Many fear that increased automation will lead to job losses, while others argue that AI can augment human capabilities rather than replace them. Establishing governance frameworks is crucial for navigating these issues.

You’ll need to consider ethical implications and strive for transparency in AI decision-making processes. Engaging stakeholders in discussions about AI’s role and its impact on the workforce can lead to more thoughtful implementation strategies. By proactively addressing these concerns, you position your organization as a leader in ethical AI deployment, fostering trust within the workforce and the broader community.

Successful Case Studies: AI in Manufacturing

Examining case studies of organizations that have successfully integrated AI into their manufacturing processes provides valuable insights. For instance, General Electric (GE) has employed predictive maintenance across its operations, resulting in reduced downtime and substantial cost savings.

Another prominent example is Siemens, which utilizes AI to enhance its production processes across its factories. By employing machine learning algorithms to optimize logistics and supply chains, Siemens has significantly improved efficiency, leading to faster delivery times and reduced operational costs. These examples highlight the real-world applicability of AI solutions and the positive impact they can have on manufacturing processes.

The Future of AI in Manufacturing

As AI technology continues to evolve, the future of manufacturing holds exciting possibilities. We’re likely to see advancements in areas such as collaborative robots (cobots) that work alongside human operators, providing assistance where it’s needed most. Furthermore, the integration of AI with the Internet of Things (IoT) will facilitate comprehensive monitoring of production processes, enabling real-time adjustments for maximized efficiency.

Imagine a fully connected manufacturing floor where machines communicate seamlessly, sharing data that informs decision-making and optimizes production. This hyper-connected environment can significantly enhance agility and responsiveness, making your operations not only smarter but also more innovative.

Strategic Value Creation Through AI

Finding strategic value in AI deployment is critical for your manufacturing success. The key lies in understanding how AI aligns with your organizational goals and objectives. As you strategize on AI initiatives, consider focusing on areas that offer the most significant potential returns, such as enhancing efficiency and improving product quality.

By setting clear goals and metrics to evaluate your AI projects, you can ensure that the investments made translate into tangible business results. This strategic alignment will position you to leverage AI not only as a tool for operational improvement but also as a driver of innovation and competitiveness in the marketplace.

The Importance of Continuous Learning and Adaptation

In the ever-evolving landscape of AI and manufacturing, the importance of continuous learning cannot be overstated. The tools and technologies around AI are rapidly advancing, and staying informed about the latest advancements will empower you to make informed decisions regarding their implementation.

Consider investing in ongoing training programs for your team to ensure they remain up-to-date on AI technologies and best practices. Keeping the lines of communication open and encouraging feedback from your team will lead to a culture of innovation and adaptability, essential for navigating the challenges and opportunities presented by AI in manufacturing.

Conclusion

In conclusion, the introduction of AI in manufacturing is reshaping production processes in remarkable ways. By leveraging AI for predictive maintenance, supply chain management, and quality control, among other areas, you can enhance operational efficiency and drive down costs. However, with opportunity comes responsibility—it’s essential to consider ethical implications, governance challenges, and workforce adaptation to create an environment where AI can flourish.

As you embark on your own journey into the world of AI in manufacturing, remember that strategic planning, continuous learning, and ethical considerations will be your guiding principles. AI is not a silver bullet, but rather a powerful tool that, when used effectively, can propel your organization to new heights of success.

If you found this article helpful, please consider giving it a clap, leaving a comment, and subscribing to my Medium newsletter for more updates. Your support means a lot!